Modern factories are racing toward high-tech, low-energy setups, and the gear that keeps machines from overheating has to catch up fast. Enter the electronically commutated, or EC, fan. Because the blades spin at exactly the right speed, these fans gulp down less electricity, hum more quietly, and last longer than most older models.

In the paragraphs that follow, we’ll break down exactly what an EC fan does, dig into its inner workings, list a few real-world applications, and spell out why a typical B2B buyer might want to make the switch. Well also mention veterans like ACDC Fan, a brand that many engineers trust for rock-solid EC hardware.

Understanding the Basics: What Is an EC Fan?

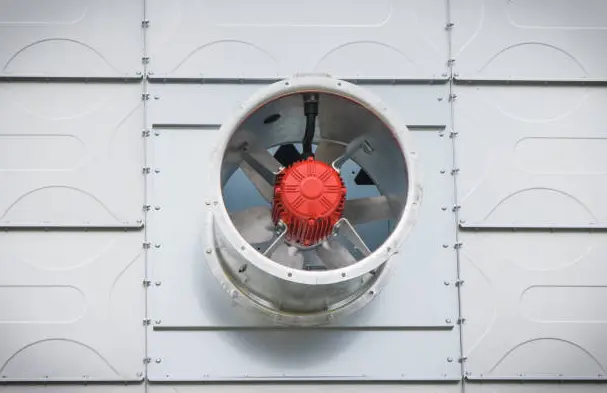

An EC fan fuses AC and DC motor traits into one compact package, which is handy because it lets airflow adjust to demand without wasting extra juice. Inside the housing, a chip converts the wall-plugged AC into smoother DC, giving the blades fine-speed control and trimming energy use by as much as half on light-duty tasks.

One thing that really stands out about EC fans is the controller tucked right inside the housing. Because the controls are onboard, you don’t need any clunky external drives to adjust the speed. The fan can then speed up, slow down, or even idle instantly when temperature or pressure numbers shift. That’s why many pros pick EC fans for today’s HVAC systems, refrigeration rigs, or any gear that needs quick, reliable cooling.

For an in-depth look at energy-smart EC fans built for heavy-duty use, swing by ACDC FAN’s online catalog https://www.acdcecfan.com/ru/products/ec-fan .

Why EC Fans Shine in Industrial Settings

Factories, data halls, telco rooms, and modern office buildings all share one big problem: keeping their electronics cool without eating into the power bill. EC fans step in here with four advantages you can count on.

Energy Savings You Can Measure

Most EC fans clock in over 90 percent efficiency once the load drops, a point where standard AC motors start to waste power. Their internal circuitry cuts back the voltage and current when full blast isn’t needed, so kilowatts stay on your bottom line.

Speed That Listens to Signals

Because the fans respond to either analog 0-10 volt or digital PWM commands, airflow can be dialed in to the cubic-feet-per-minute you actually require. That real-time tuning is a lifesaver when a processor spikes, a chiller kicks on, or a data rack suddenly wakes up.

Longer Service Life

Engineers love the natural durability of EC fans. Their motors run smooth, and the light mechanical load cuts wear and tear. Many models toss in soft-start routines, fault alerts, and guards against overheating and electrical spikes. Just set them up and forget, long-term reliability is basically built in.

Low Noise Operation

Plug an EC fan into a quiet lab or classroom and it’s almost like nothing turned on. The fan hum is faint, the electrical buzz is even fainter. That low-profile sound comfort lets architects win over clients who can’t stand extra noise.

Simplified System Design

Speed control is baked right into the EC package, so external variable drives vanish from the bill of materials. Fewer boxes and less control wire mean quicker rack builds and slimmer budgets for OEMs. Installers enjoy the clean, tidy finish and get the job done a day ahead of schedule.

Common Industrial Applications of EC Fans

EC fans started as a specialty item but now fill up order lists in almost every efficiency-minded factory. Their footprint keeps expanding into new spaces, mostly where brains and bucks meet. Here are the biggest neighborhoods on the map.

Telecommunications and Data Centers

Inside a data hall, a rack of servers bleeds heat like a summer sidewalk. EC fans circulate the air, shave kilowatts, and stop processors from throwing thermal fits. The same rotor-sensor combo cools telecom cabinets and little cooling modules scattered on telecom poles.

HVAC and Building Automation

A rooftop unit that spins EC blades can drink less power and still keep tenants comfortable. Utility meters watch the savings add up, and building inspectors nod because the gear meets the latest energy codes. Facility managers appreciate the low-voltage whisper through the ductwork as much as the lower light-bill shock at month-end.

Refrigeration and Cold Chain Logistics

Perishable goods don’t wait around, so keeping them at the right chill is not optional. EC fans change speed on the fly, matching airflow to what the load really needs, and that small tweak can slice energy bills in half.

Industrial Control Panels

Inside the metal box that runs the factory, even a tiny surge can fry delicate boards. EC fans hush that heat for hours and hours while barely making a sound, so the guts of the machine stay calm.

Cleanrooms and Laboratories

In a drug plant or a chip fab, a whiff of bad air or a stray degree can ruin a batch. EC fans keep a steady breeze going and barely notice when the filters clog, letting the big scrubbers do their job without interruption.

Choosing the Right EC Fan for Your Application

Picking the right EC fan is a balancing act much like walking a tightrope- good performance, fair price, plug-and-play setup.

Size and Form Factor

You can find EC fans the size of a coffee cup or as big as a desktop phone panel. Measure the nooks and crannies first or else the fan will fit in the box and the wires wont.

Voltage and Power Range

Ninety-eight percent of the time the voltage is either 115, 230, or a multi-range model that covers both sides of the pond. Double-check the label before clicking purchase, because the wrong input can turn a fan into a paperweight.

Airflow and Pressure

To figure out how much air your setup needs, run the numbers in CFM or m/h. If the path is windy because of thick filters or narrow ducts, you’re going to want a fan that can punch out extra static pressure.

Control Method

Most modern EC fans play nice with PWM or the 0-10V signal that lets you dial in the speed. Double-check that your existing control box can send the right message before you bolt anything in place.

Environmental Protection

Dust and water can ruin a good motor, so pick an IP-rated fan if you’re working in a dirty or soggy spot. Also look at the temperature range; a unit that overheats today won’t make it to payday.

Certifications Industry stamps like CE, RoHS, or UL matter if your gear is crossing borders or going into hospitals. Compliance paperwork is boring, but it saves headaches later.

ACDC FAN’s Role in Advancing EC Fan Solutions

For more than 20 years, ACDC FAN has been turning out AC, DC, and EC blowers that just work, and keep on working. Engineers in factories, telecom rooms, and medical labs trust that kind of reliability-even when the deadline looms.

ACDC FAN builds the EC Series around everyday B2B challenges:

- It handles both 110-volt and 220-volt grids without a hitch.

- Engineers can tinker with control settings via PWM commands or grab a tach signal on the fly.

- Even when no one’s watching, its power footprint stays small.

- An IP rating keeps dust and moisture on the outside where they belong.

- Certificates from almost every corner of the globe mean no last-minute airport tests.

For customers with special needs, the shop does OEM and ODM work. Ask for a shorter casing, a different plug, or a wider voltage window and, odds are, the team can whip it up.

Factories are swapping guesswork for data, and that’s jacking up the need for smarter cooling.

EC fans step in here, acting less like basic blowers and more like quiet partners in an energy-lean setup.

With names such as ACDC FAN backing their claims, engineers find a pathway to gear that trims bills, meets green targets, and still plays nice with tomorrow’s high-tech plants.

Also Read-The Safest Ways To Sell Your Tiffany Jewelry Online