Understanding Predictive Maintenance

In today’s competitive landscape, industrial organizations face immense pressure to optimize operations, ensure asset reliability, and manage operational costs effectively. Predictive maintenance is emerging as a crucial strategy, leveraging real-time data, advanced analytics, and artificial intelligence to predict machinery failures before they disrupt production. By taking a proactive approach, organizations can plan interventions precisely when equipment shows early signs of deterioration, rather than waiting for breakdowns or scheduling maintenance at arbitrary intervals. This approach leverages the capabilities of water system maintenance products, along with other cutting-edge tools, to further enhance operational resilience and minimize costly interruptions.

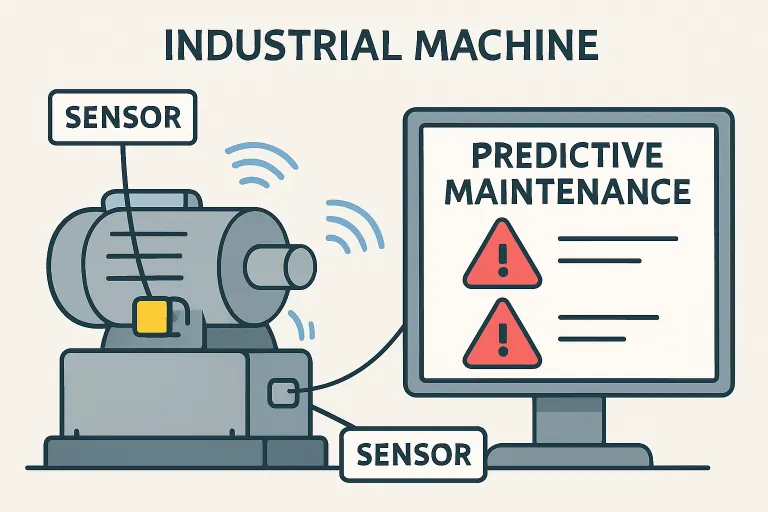

Predictive maintenance replaces traditional preventive approaches by using sensors and monitoring systems to detect early faults, reducing unnecessary servicing and preventing serious issues. As digital transformation advances, organizations see it extends asset lifespan, lowers failure risks, and improves safety and sustainability. Leading sources like McKinsey highlight how predictive strategies boost productivity and cut costs, marking a key shift toward more reliable and efficient operations.

Key Components of Predictive Maintenance

- IoT Sensors:These devices gather continuous streams of data directly from equipment. By monitoring operating parameters such as torque, humidity, and rotational speed, IoT sensors provide real-time visibility into asset health and environmental conditions.

- Data Analytics:Predictive maintenance relies on sophisticated analytical software to interpret massive volumes of sensor data. These tools rapidly identify deviations from normal operating patterns, helping maintenance teams focus on the most urgent performance anomalies.

- Machine Learning:At the core of predictive maintenance strategies are AI-driven algorithms. Machine learning models are trained on historical performance data and failure records to continuously refine algorithms and improve prediction accuracy as more data becomes available.

Benefits of Implementing Predictive Maintenance

Industrial leaders adopting predictive maintenance unlock several compelling benefits:

- Reduced Downtime:With early warnings from condition monitoring, maintenance can be performed during scheduled windows, minimizing production disruptions and improving scheduling flexibility.

- Cost Savings:By targeting interventions precisely when needed, organizations can dramatically reduce labor costs, spare part inventories, and expenses associated with emergency repairs or extended outages.

- Extended Equipment Lifespan:Timely servicing prevents minor issues from escalating, reducing wear and tear, and allowing machinery to function at peak for longer periods. This added longevity directly impacts the bottom line and supports capital preservation.

Industry Applications and Success Stories

Predictive maintenance is driving innovation and efficiency across sectors:

- Manufacturing:Companies that implement predictive maintenance have experienced a 12% increase in productivity. Real-time asset monitoring reduces machine failure rates, streamlines production schedules, and enhances product quality.

- Energy Sector:Power generation and distribution companies are moving toward advanced maintenance models that leverage data from smart grids and industrial systems. By incorporating predictive analytics, they extend the lifespan of critical infrastructure and optimize asset utilization.

- Mining:Mining operations, often remote and resource-intensive, have realized notable reductions in both equipment downtime and maintenance costs. Predictive systems detect early warning signs in high-value assets such as haul trucks and crushers, supporting safer and more productive operations.

As highlighted by Forbes, predictive maintenance is not just a technological advantage but a competitive necessity for forward-thinking industries.

Challenges in Adopting Predictive Maintenance

Despite its benefits, widespread adoption of predictive maintenance can present several challenges:

- Data Management:Modern predictive systems generate vast quantities of sensor data. Efficiently storing, cleaning, and processing this information requires robust IT infrastructure and scalable analytics platforms.

- Skilled Workforce:Maintenance professionals must develop new expertise in data interpretation, sensor calibration, and AI-driven diagnostics to stay competitive. Upskilling and training programs are essential for supporting a data-driven culture on the shop floor.

- Initial Investment:Upfront expenditures for sensor installation, software procurement, and employee training can be substantial. However, organizations focused on long-term returns find that significant reductions in operational costs and risk exposure shorten payback periods.

Future Trends in Predictive Maintenance

Industry forecasts indicate that predictive maintenance will continue to evolve as digital technologies and artificial intelligence become more accessible and integrated:

- Integration of AI and Machine Learning:As AI models mature, failure predictions will become more nuanced, and recommended maintenance actions will be increasingly automated, maximizing uptime and reliability.

- Advancements in IoT Technology:New generations of sensors are delivering unprecedented insight into asset performance, allowing granular analysis of operational behaviors and failure modes.

- Cloud Computing:The scalability and flexibility of cloud platforms enable rapid deployment of predictive maintenance solutions across multiple sites and geographies, unlocking enterprise-wide collaboration and learning.

Emerging innovations are also paving the way for integration with digital twins and virtual simulation environments, driving even greater efficiencies and scenario planning for asset maintenance strategies.

Conclusion

Predictive maintenance is fundamentally reshaping the industrial landscape, propelling organizations from legacy reactive maintenance to a data-driven, proactive future. By investing in smart sensors, advanced analytics, and AI, companies can reduce downtime, minimize maintenance costs, and extend the life of mission-critical assets. With technology advancing rapidly, adopting predictive maintenance is quickly becoming an indispensable strategy for industrial success, helping businesses build resilience, ensure operational continuity, and achieve sustainable growth in an ever-evolving marketplace.

Read more: Term Life Policy Explained: Affordable Protection for Families – Dimensions Script

The Runway to Reality: How to Rock Curly Extensions for Black Hair at Any Event – Dimensions Script

Collagen Stimulation Treatments for Facial Rejuvenation – Dimensions Script