Maintenance strategies need to change in the fast-paced industrial environment of today to meet the growing demands for cost-effectiveness, safety, and operational efficiency. Infrared thermography is one innovative technology that is revolutionizing maintenance procedures in a variety of industries. By using this non-invasive diagnostic tool, experts can find abnormalities in infrastructure and equipment before they cause failure, saving businesses money on downtime and extending asset lifespans. Infrared thermography is revolutionizing proactive and predictive maintenance for mechanical and electrical systems. Businesses can greatly improve their capacity to spot hidden problems and make data-driven decisions by incorporating this technology into routine maintenance procedures.

Comprehending Infrared Thermography for Maintenance

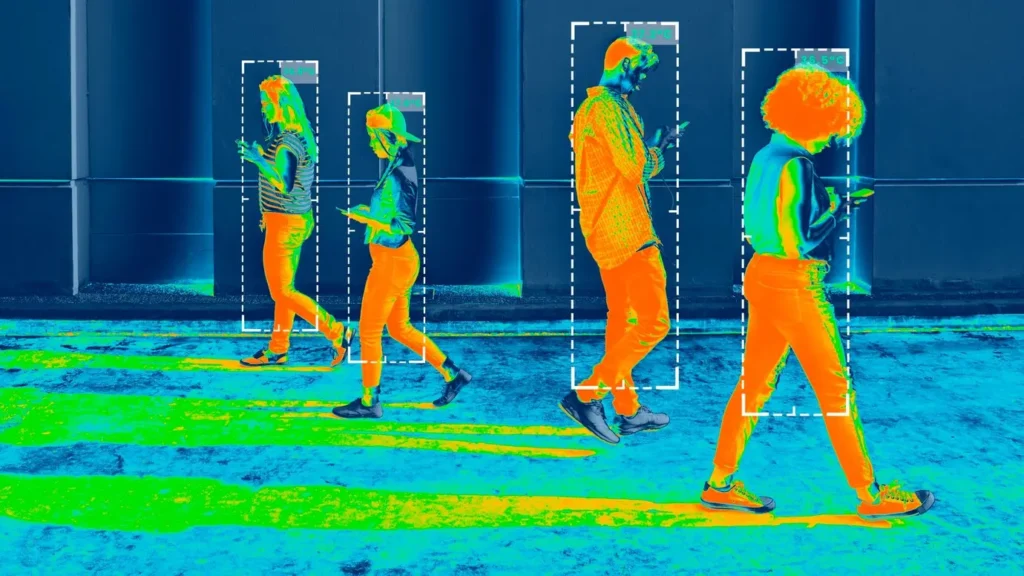

Taking thermal pictures, or thermograms, that show temperature changes and heat patterns on an object’s surface is known as infrared thermography. Without requiring direct contact or equipment shutdown, these thermal images can identify possible issues because excessive heat is frequently an indication of stress, wear, or failure. Because of this, infrared thermography is particularly helpful for checking live electrical panels, circuits that are overloaded, or mechanical parts that are not aligned properly. Technicians can more easily recognize unusual heat signatures thanks to the technology’s ability to detect infrared radiation and convert it into one visual image. Unplanned downtimes and catastrophic failures, which are expensive and potentially hazardous, can be avoided with this early detection technique.

Benefits Compared to Conventional Inspection Techniques

Infrared thermography has many benefits over conventional inspection methods that raise the standard and effectiveness of maintenance. One benefit is that it is a non-intrusive and non-destructive technique that enables technicians to evaluate systems in operation. This saves time and lowers labor costs by doing away with the need for shutdowns or disassembly. Furthermore, thermal imaging yields results instantly, allowing for speedier diagnosis and remediation. Thermography provides measurable data, which improves the impartiality and consistency of inspections in contrast to some traditional techniques that might rely on subjective judgments. Together, these advantages result in longer equipment lifespans, more dependable maintenance procedures, and significant cost savings over time.

Uses in Various Industries

Infrared thermography has a wide range of applications in many different industries. It is employed in the manufacturing industry to check production lines, motors, and bearings for overheating parts. It assists in keeping an eye on solar panels, transformers, and substations in the energy sector to guarantee peak performance. It is used by building maintenance teams to find moisture intrusion behind walls, HVAC inefficiencies, and insulation failures. Thermography is used even in the maritime and aviation sectors to examine structural integrity, control panels, and turbines. For industries where dependability, safety, and uptime are essential, effective infrared thermography inspection has emerged as a crucial tool because it provides real-time insights without interfering with operations, so look into it ASAP.

Improving Strategies for Predictive Maintenance

The concepts of predictive maintenance, which aim to foresee failures before they happen, are perfectly aligned with infrared thermography. Thermal inspections can be an essential part of condition monitoring when incorporated into a predictive maintenance program. To identify patterns that point to deterioration, technicians can create baseline temperature profiles and compare subsequent readings. A motor that continuously operates hotter over months, for example, may be on the verge of failure because of electrical imbalance or bearing wear. Businesses can minimize operational disruptions, prevent emergency interventions, and schedule repairs during planned downtimes by spotting such trends early. A more proactive and strategic approach to asset management is the result.

Considerations for Training and Implementation

Even though infrared thermography has many advantages, proper planning and training are necessary for its successful application. Technicians need to know how to use thermal cameras, decipher thermographic data, and identify false positives brought on by external circumstances. The qualifications and ability of thermography professionals to perform precise inspections are ensured by certification programs and standards. To track findings, create work orders, and keep thorough equipment histories, organizations should also integrate thermography with computerized maintenance management systems (CMMS). In addition to purchasing the appropriate equipment, a successful implementation strategy calls for maintenance teams to adopt a culture of ongoing learning and data-driven decision-making.

By offering a quick, precise, and non-invasive method of identifying hidden issues, infrared thermography is revolutionizing the standards of maintenance quality across industries. Incorporating infrared thermography into routine maintenance procedures will be crucial for long-term sustainability, safety, and competitiveness as industries continue to embrace digital transformation.

Also Read-What Technologies Are Transforming Clinical Research Organizations?