The world of renewable energy is booming — there’s no denying that. However, within different photovoltaic (PV) systems, maintaining reliable surge protection directly correlates to safely operating and maintaining the system’s longevity, as well as ensuring consistent performance. One critical question that project managers, system integrators, and engineers need to face is whether to select the voltage class DC SPD 1000V or DC SPD 600V surge protection devices.

As evident from the Volt and SPD selections above, choosing appropriate SPDs requires more than just a superficial glance at the system’s architecture or a singular focus on the voltage rating; it necessitates comprehensive dissection including risk appetite, surrounding conditions, and ROI longevity. Any company that functions in the capacity of a business in the solar or renewable field would be wise to leverage the insight provided by a reputable lsp surge protection device manufacturer. They will allow access to unparalleled SPDs and with unmatched compliance guarantees and product assurance.

This paper delves into the differences between the use cases and the best solutions provided for each, knowing that each case involves 1000V and 600V DC SPDs.

Knowing The Basics Of Devices That Protect From Surge On Direct Current (DC SPDs)

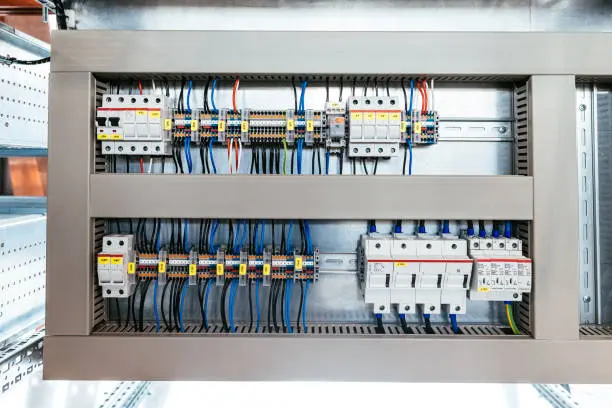

Surge Protection Devices (SPDs) are integrated within electrical systems in order to protect critical components from transient over-voltage threats such as lightning strikes, switching, or ground faults. In renewable energy systems, particularly those that utilize solar panels, plants powered by solar systems rely on SPDs for safeguarding:

- PV Modules

- Inverters

- Charge Controllers

- Battery Banks

- DC Disconnect Switches

Unlike AC systems where current goes to zero naturally, DC systems are more prone to danger within prolonged arcs and consistent over-voltage damage. Hence, surpassing direct current (DC) installations, effective surge protection is more essential.

A DC surge protective device classified as DC SPD 1000V or 600V is based on the comprensible maximum continuous operating voltage it can endure. Higher voltage rated SPDs are generally used for larger solar systems or utility scale installations, whereas lower voltage SPDs are sufficient for smaller residential setups along with commercial scales.

Application Scenarios: Where 600V And 1000V DC SPDs Fit

To decide if DC SPD 1000V is more appropriate than the 600V version or vice versa, it is crucial to look at the solar power system’s voltage ratings and configuration.

Use Case for DC SPD 600V

- Small-scale solar power systems (typically below 10 kW)

- Residential and light commercial buildings

- Battery-powered systems with lower voltage cutoffs

- Off-grid and microgrid configurations with a limited number of string panels

You can find 600V SPDs in older solar installations and lower-capacity hybrid systems with integrated battery storage. These systems tend to have a lower maximum open-circuit voltage (Voc) along with fewer strings in series.

Use Case for DC SPD 1000V

- Commercial and industrial PV installations

- Utility-scale solar farms

- Large string inverter configurations

- Central inverter systems operating at high voltage

For systems with longer PV strings or those that maximize output by pulling voltage towards the inverter’s design limit, DC SPD 1000V works perfectly. Modern inverters are often rated up to 1000V, which makes this SPD type essential in contemporary solar designs.

Due to the high voltage limitation, these surge protection devices must come from a reliable lsp surge protection device manufacturer while meeting the IEC 61643-31 and UL 1449 international standards.

Evaluating Protection, Endurance and Compliance Performance

The functionality of a surge protection device in real life is not solely a function of its voltage rating. Other factors such as response time, nominal discharge current (In), maximum discharge current (Imax), and voltage protection level (Up) also contribute.

Surge Capability

Both 600V and 1000V SPDs are capable of withstanding large energy impacts, usually surges of 20kA to 40kA or even more. However, DC SPD 1000V devices typically have more robust internal components to withstand greater energy impacts for longer periods of time.

Reaction Time

Both versions have relatively the same response time, which is in the range of nanoseconds. Those from an established lsp surge protection device manufacturer are known to have faster clamping action resulting in less downstream component residual voltage.

Endurance

SPDs with higher voltage ratings offer better mechanical endurance which makes them ideal casing for solar power equipment. This feature, combined with effective sealing, means that they can withstand harsh outdoor conditions such as solar farms or desert installations.

Conformity to Standards

Relevant global standards for the following have to be met for DC SPDs:

- DC Applications: IEC 61643-31

- North American Installation: UL 1449 Fourth Edition

- Photovoltaic System Design: IEC 60364-7-712

Product design and equipment selection compliant to lsp surge protection device manufacturer standards eliminates liability risk in case of equipment failure.

Financial Discourse and Proactive Spending

Relative to 600V models, DC SPD 1000V units have higher initial costs, but are most economical in the long run due to SPDs having:

- Elastomeric Seals: Increased Durability: Resulting in less maintenance performed.

- Expanded Configuration Lowered SKU

- Increased System Compatibility: Enhanced scope as system capacities scale up.

In comparison to Retail, B2B buyers including solar EPC contractors, developers, and industrial facility managers tend to prioritize the total cost of ownership rather than the initial product price.

Additionally, system upgrades over time are capable of exceeding 600V. Employing a DC SPD 1000V from the start allows for ease in scalability without needing to reconfigure the protection scheme.

Choosing the Appropriate SPD Partner for Your System

Selecting a trusted supplier also goes beyond their technical specifications. An lsp surge protection device manufacturer will undoubtedly offer more than just components; there will also be advisory support, compliance assistance, and often tailored solutions.

Use these points as a guide when looking for a partner:

- Extensive experience in solar SPD applications

- Products are provided with test results to international standards

- Custom made voltage ranges or configurations

- Engineering Support Prior to Sale

- Services rendered post-sale and on-site defect troubleshooting

With the right manufacturer, you’ll have the expertise necessary to ensure that your surge protection strategy is tailored appropriately in consideration of your energy goals, system design, and maintenance plan for the long term.

Conclusions: Correctly Selecting Your Renewable Project

Understanding the use case helps bring clarity, especially when contrasting DC SPD 1000V and 600V models. The selection ultimately boils down to your system’s configuration voltage, installation size, and desired life span. 1000V SPDs are more compatible and have greater surge handling capacity which is preferred for large scale or high-efficiency systems. 600V SPDs, on the other hand, remain viable for smaller, cost sensitive projects that have modest power demands.

In every case, working with a reputable lsp surge protection device manufacturer makes sure you are purchasing a product and investing in quality, protection, support, and value during the lifetime of your renewable energy system.

The protection you implement today ensures output, reliability, and continuity for years to come. Make this investment count with the right class of voltage and the right partner.

Also Read-Harnessing Technology for Efficient Home Management